우리는 최고의 공급자가 되기를 바랍니다 해양용 원뿔형 고무 방파제 중국에 있는

해양 원뿔형 고무 방충기 설명:

그 해양용 원뿔형 방파제 은 지속적인 제품 개발의 결과입니다. 이 방파제 설계는 25년 이상 전에 세계 시장에 소개된 셀 방파제를 기반으로 합니다. 이 유형의 방파제는 성형 방파제 제품 중 최신으로 간주될 수 있습니다. 뛰어난 에너지 능력을 제공하면서도 낮은 반응(설계 압축 변형률이 52.5%에서 70%로 증가하지만 반응력은 동일하게 유지됨)을 제공합니다.

원뿔형 고무 방파제 는 모든 방파제 유형 중 가장 높은 에너지 흡수율과 가장 낮은 반응력을 가지고 있습니다. 높은 효율성 덕분에 우수한 성능과 더 적은 비용을 제공합니다. 모든 원뿔형 방파제 일체형 몰딩이므로 견고하고 수명이 길며 설치가 쉽다. 대부분의 프로젝트에서 전면 프레임은 일반적으로 콘 타입 방파제 시스템과 함께 사용된다. 일반적으로 전면 프레임에는 강판과 UHMW-PE 패드가 포함되어 있다.

대부분의 응용 분야 중 일부는 콘 타입 방파제 해상 오픈 부두, 컨테이너 터미널, 유류 부두 및 기타 대형 부두에서 사용되며, 이는 높은 전단력을 견디고 큰 패널 무게를 처리할 수 있으며 가장 높은 에너지 반응 비율을 가지고 있다. 이를 역방향으로 설치하여(작은 면이 부두 벽에 맞닿도록) 설계자는 좁은 항구 구조물에서 발판 면적이 제한적인 경우 이러한 종류의 방파제를 사용할 수 있다.

해양 콘 고무 방파제 시스템의 부속품:

원뿔형 고무 방파제

체인 및 부속품(U자描錨, 브라켓 & 샤클)

방청 도료로 칠해진 강판

UHMW-PE 표면 패드

방파제 고정 앵커 및 볼트

해양 콘 고무 방파제의 특징:

단위 무게당 매우 높은 에너지 흡수량.

큰 접안각과 전단력에서도 우수한 성능.

다양한 사이즈 선택 가능(300-2000mm)

표준 및 중간 화합물 선택 가능.

모든 하중 조합에서 성능을 유지하는 안정된 기하학적 구조.

검증된 설계.

설치가 쉽고 빠름.

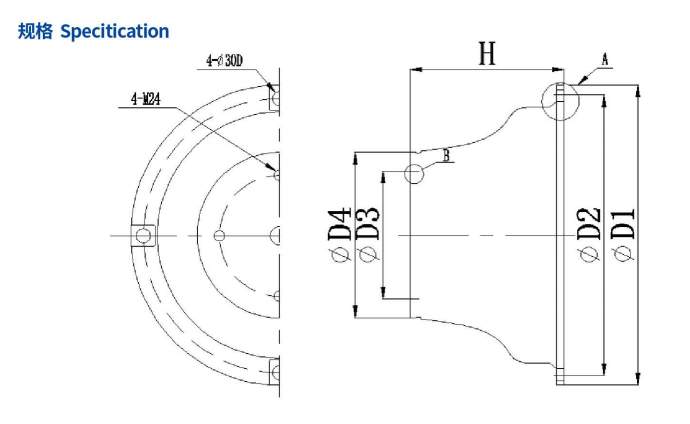

| 모델 Type | H(mm) | D1 ((mm) | D2(mm) | D3(mm) | D4(mm) | 공 수 Holes |

| C500H | 500 | 750 | 675 | 325 | 425 | 4 |

| C600H | 600 | 900 | 810 | 390 | 510 | 6 |

| C700H | 700 | 1050 | 945 | 455 | 595 | 6 |

| C800H | 800 | 1200 | 1080 | 520 | 680 | 6 |

| C900H | 900 | 1350 | 1215 | 585 | 765 | 6 |

| C1000H | 1000 | 1500 | 1350 | 650 | 850 | 6 |

| C1100H | 1100 | 1650 | 1485 | 715 | 935 | 6 |

| C1150H | 1150 | 1725 | 1550 | 750 | 998 | 6 |

| C1200H | 1200 | 1800 | 1620 | 780 | 1020 | 8 |

| C1300H | 1300 | 1950 | 1755 | 845 | 1105 | 8 |

| C1400H | 1400 | 2100 | 1890 | 930 | 1190 | 8 |

| C1500h | 1500 | 2400 | 2160 | 1060 | 1360 | 8 |

| C1600H | 1600 | 2700 | 2430 | 1190 | 1530 | 8 |